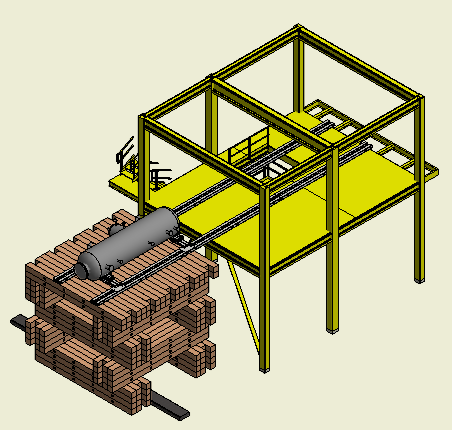

Removing vessels from remote areas can be challenging. This vessel was one floor up around twenty feet in elevation. The vessel had a boot that dropped down through the first floor and was inset of the floor by six feet. The vessel also was inward from the opening by thirty feet. To remove the vessel, the vessel required rotation to remove the boot from below and then skid the vessel to the entrance around thirty feet. Then the vessel had to be skidded out onto a platform (designed by Formula/Bradley) so a crane could remove it twenty feet into the air. Once completed a new vessel was replaced in the old location with a similar boot configuration.

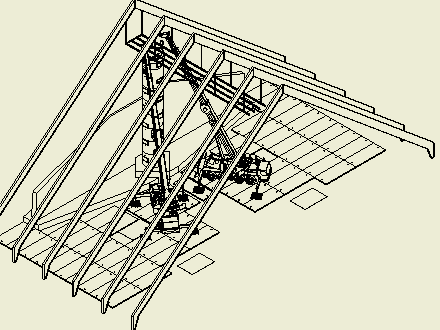

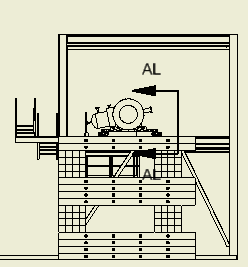

This illustration and others below shows the vessel boot and the floor opening it was situated in. The vessel needed rotation to remove it.

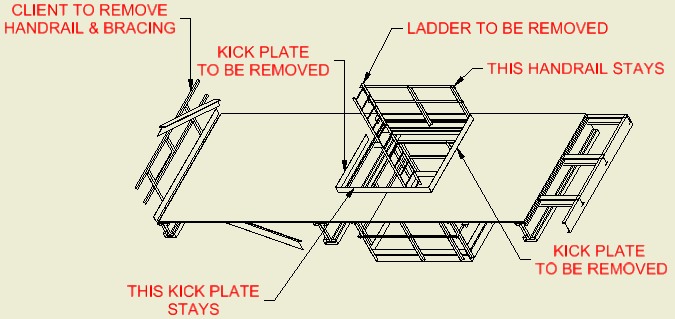

Actual photos of work completed. Shown is the vessel location, below is the pad built to skid the vessel out and onto for removal. This project was defined as priority for other work to be executed, so the timeline was limited for removal and replacement. The client has requested many more projects similar too this over the last few years.

This type of work has become very familiar to Formula/Bradley since the plant sites in Western Canada are aging and equipment needs replacement. Removal of this equipment was not part of the thought process when building these plants and this process has proven itself to be very beneficial to the client.