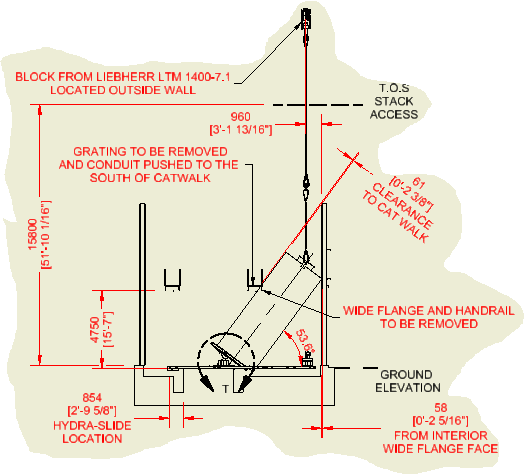

This vessel was small but it was located in a very difficult location for removal. This vessel was vertical, standing over two floors. The second floor had an opening for the vessel to be vertical and the vessel was attached to a stack that projected through the roof around 120 feet. This vessel had to be lowered down and be directed under the upper floor into the building and then be removed through the wall. The tolerances were very tight and requested by the client.

Platforms grating and conduit could not be moved after the review of this drawing package. The conduit was old, and the client did not want to remove it for wiring could be broken and to repair could take months. Since three days were set for the removal of the vessel all interferences had to be negotiated around. The vessel had to drop below the upper floor, so the design of the tilt frame required major study and review. This frame had to be hydraulic for lifting as the vessel came around the upper catwalks and conduits. The top of the vessel was attached to a Liebherr LTM 1400, with a capacity of 500 ton. Operational the crane had to work with the tilt frame inside the building being operated by the supervisor. Radio contact was imperative.

The project was a success at 2 ½ days and the client was very impressed.